Technology

Licopharm has developed ecological insulating boxes made out of paper which, in combination with the appropriate cooling media, keep temperature-controlled medical and pharmaceutical goods cool during their transport without any loss of quality. Based on its own innovative and sustainable shipping insulation made of cellulose fibers, Licopharm has created a sustainable alternative to expanded polystyrene (EPS) that revolutionizes the mobile cooling of temperature-sensitive medical and pharmaceutical products. For this purpose, waste paper is shredded in a special process and finally processed into insulating mats, which are installed in the Licopharm WRAPandCOOL systems.

In addition to ecological insulating packaging, the company offers a range of different cooling media, which are tailored to specific temperature requirements and size needs. The in-house production facility in Bavaria enables strong flexibility for meeting individual customer requirements and is enabling the highest quality standards.

Sustainable Insulation Technology

Sustainability and resource efficiency play an essential role, from production to disposal of our insulating packaging.

Moreover our system minimizes the disposal effort for the end customer by reducing the amount of waste to a minimum.

That’s why cellulose!

Energy & Material Efficiency

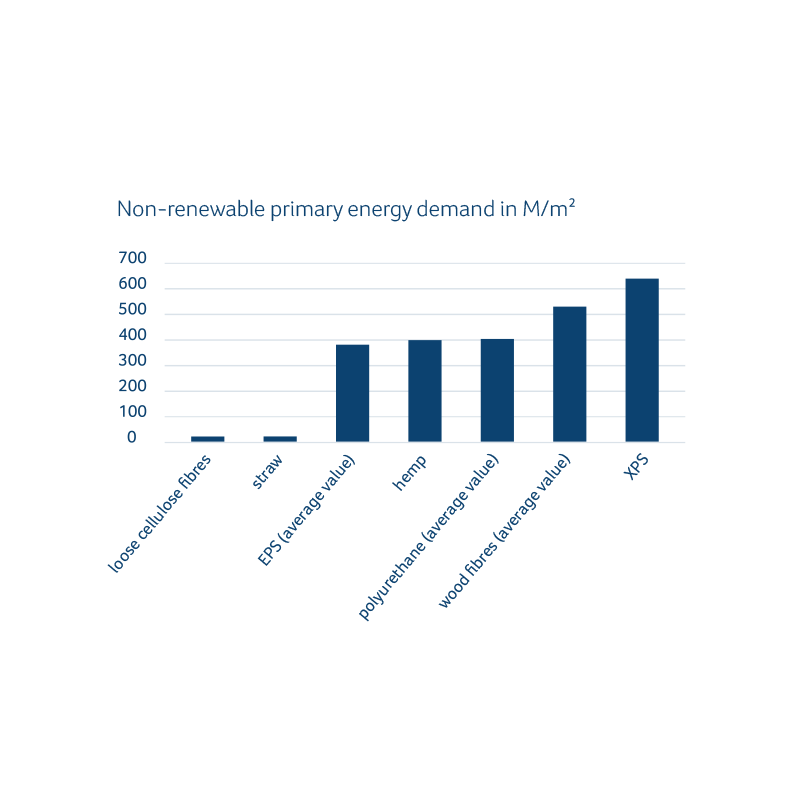

VDI Centre for Resource Efficiency conducted a study on behalf of the German Federal Ministry of the Environment and compared the energy and material efficiency of various insulating materials. The result: Among those materials that can also be used for shipment cooling, “in the overall evaluation (…) insulation out of loose cellulose fibres comes definitely out on top”! An extremely low energy consumption with negative carbon emissions and recyclability at the end of the life cycle are the reasons for that.

(source graphic: VDI ZRE Publikationen: Kurzanalyse Nr. 7)

Coolpack Technology

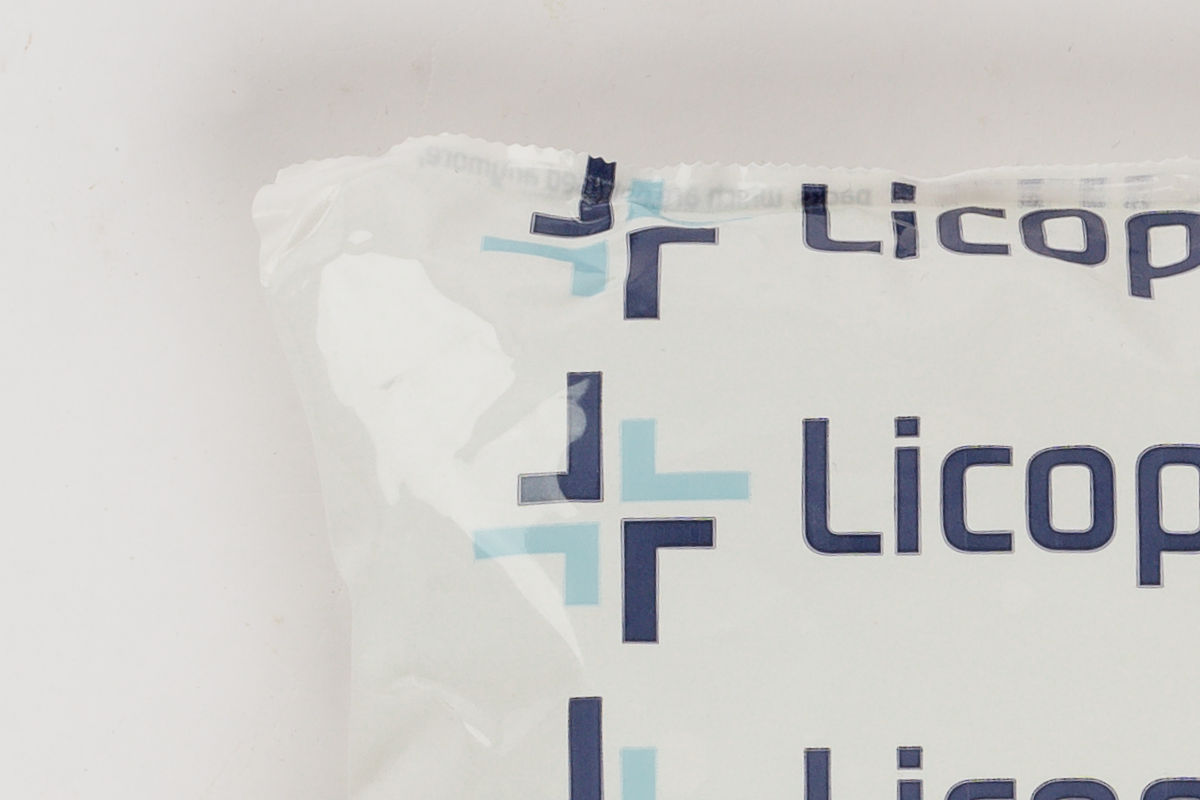

- The thin outer skin of the coolpacks is made of a material, which is 100% recyclable

- It has excellent cooling properties thanks to its special filling

- The corners of Licopharm coolpacks are rounded to not damage your products during transport

- The quality of our products is confirmed in regular checks

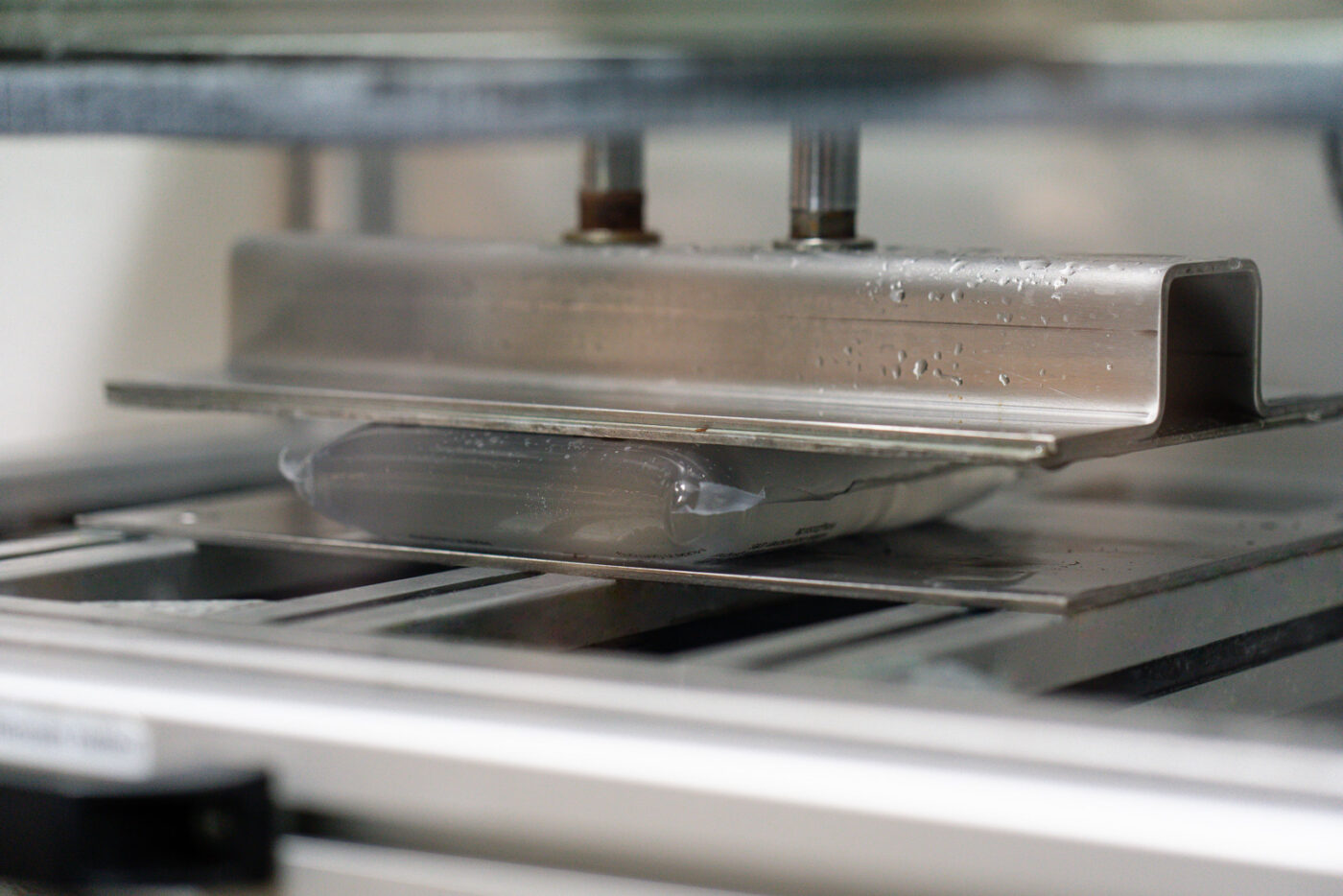

- In addition to climate tests, the Licopharm Coolpacks get tested in a pressure test to meet the high requirements of refrigerated shipping

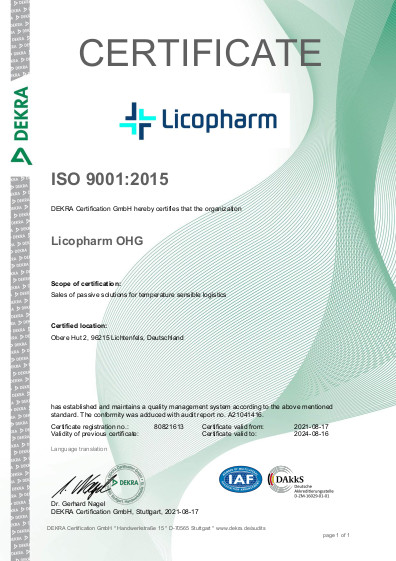

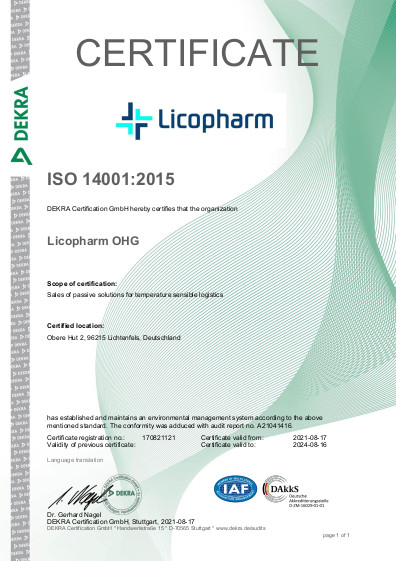

- Our high quality standards were certified in the context of the ISO 9001 & 14001 certification

ISO Certification

Licopharm is certified according to DIN EN ISO 9001:2015 (Quality Management) und DIN EN ISO 14001:2015 (Environmental Management).

Consulting & Tests

If our standard solutions are not suitable for you, we are happy to work with you to develop the optimum passive cold storage system for your requirements. Our team will develop an optimal solution, precisely tailored to your requirements, by conducting simulations and individual tests in our modern climate chambers

Thanks to our in-house production facility in Lichtenfels, Upper Franconia, we are able to deliver even customised products quickly and efficiently.